LaserTools LMD

netvision offers a manufacturing solution for experts.

The solution for any type of laser process

LaserTools is the simple and intuitive solution for any type of laser process. With LaserTools, processing of complex parts can be performed quickly, efficiently and in high quality. The LaserTools solution combines reliable, automated toolpath generation with ease of use. Collsions with parts, fixtures or machine components are ruled out before the program is actually transferred to the machine. The offline programming solution LaserTools cuts down on time consuming teach-in procedures and waste of machine resources.

Main advantages and benefits of LaserTools

1. Integrated CAD for perfect preparation of models

Well prepared CAD models are the foundation for automated toolpath generation. netvision LaserTools integrates a set of tools to create, modify and repair solid and surface models. It also provides scanner interfaces and the ability to import point clouds, including mesh conversion, smoothing, reduction and repair tools.

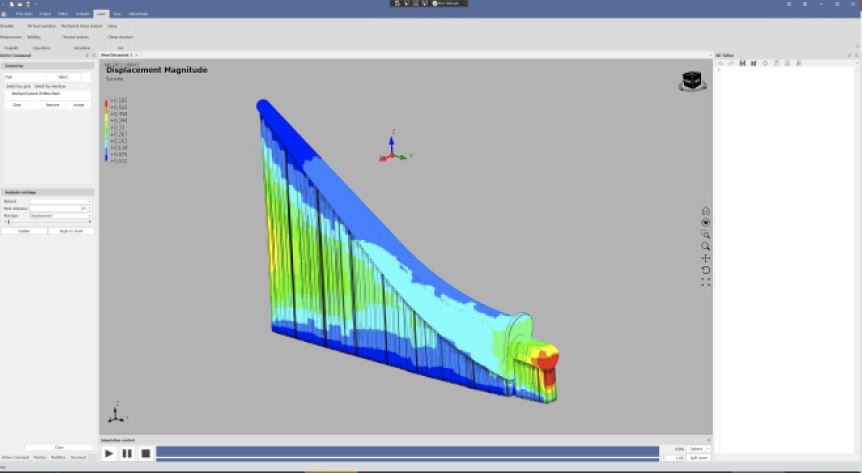

2. Integrated AM simulation (optional)

The integrated thermo-mechanical and melt-pool simulation module allows extensive model and production process analyses. Thus, potential deformation problems can be identified and solutions can be applied to the model before starting the toolpath calculation and, finally, the production process.

3. Automated and flexible toolpaths

The intelligent selection process supports users when creating toolpaths while always providing options for manual modifications aswell. Flexible, interactive adjustment functions allow machine orientation and process parameter modifications at any point in the program. Options like multi-axis-limits, toolpath extension or alternating offsets can be inserted at any position and orientation.

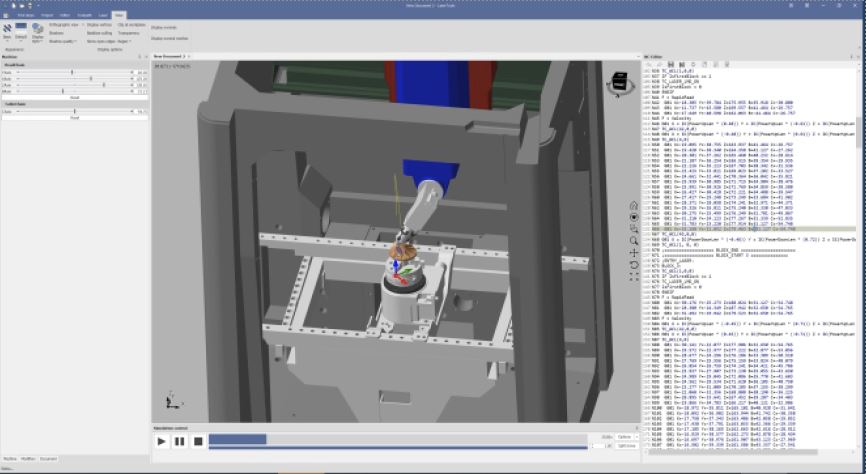

4. Virtual production environment

The integration of the machining environment‘s digital twin in the

netvision LaserTools project provides a constant overview of the entire manufacturing process.

Manual toolpath modifications are reflected instantly in the collision analysis. The virtual CNC controller allows immediate updates of the NC program after manual modifications are made.

LaserTools - LMD components

LaserTools — CAD

- 2D functionality to create and modify 2D geometry

- Solid and surface model creation and modification

- Generation of part and assembly drawings

- Repair and stitching of solid and surface models

- Multi-surface offset with automatic trimming and extension

- Automatic or manual curve smoothing

- Thermo-mechanical and melt-pool simulation (optional)

- Point cloud to mesh conversion (optional)

- Import and modification of scanned data (optional)

- Supported file formats:

DXF, DWG, STEP, IGES, STL, BREP, 3DS, OBJ, JT, IDW, IPT, IAM, 3DM

LaserTools — CAM (toolpath generation)

- 3D build by layers

- Multiaxis surface coating

- Special mode for scan to target model repair

- Automated contour optimization and smoothing

- NURBS- and arc interpolation (CIP conversion)

- Interactive toolpath modification

- Guide curve definitions for optics adjustments

- Integrated and fully customizable technology database

- Technology adjustments for start and end overlap

- Template-based geometry programming

LaserTools — Virtual machine simulation

- Fully integrated digital twin based on the actual NC code

- Visualization of critical axis acceleration

- Bi-directional links between machining operation and NC code

- Best-Fit function of optimized placed of parts

- Breakpoint definition for easier detail analsys

- Simulation of HMI commands (for ex. simulation of fixtures)

- Simulation of subroutines and machine cycles

- Version management for NC programs

- Transformation of the NC program

- Integrated NC editor

LaserTools — New and more efficient postprocessor generation

The virtual machining environment inside LaserTools was extended by a completely new postprocessor technology. The bi-directional link between NC code and the machine controller allows conversion between different machines and controllers even if the kinematic model differs. The postprocessors can be written in any .NET language (C#, VB.NET etc.). This makes modifications or implementation of new features easy and reliable.

LaserTools — are there any questions? Write to us or call us!

LaserTools also provides manufacturing solutions for milling, turning, laser cladding and integrates a flexible PDM/TDM system.

Please contact us for more information.

NetVision: There's more behind it!

The Netvision GmbH & Co. KG was founded in 1993. By today we are one of the leading system houses and consultants around the city of Ulm in southern Germany. We assist our clients in the realization of complex projects in the fields of construction, production and data management, IT service management and business management. As a full-service partner we offer 20 years of experience in the project business with specific expertise in software development and in-depth industry knowledge.

The netvision team offers you more than the standard, using holistic consulting and service approaches: We understand our customers, have sound industry knowledge, record processes and develop ideas. This allows us to deliver high-end products, to adapt systems to requirements and to be there for you well beyond project phases. The NetVision team is looking forward to the new challenges your projects will bring!